Table of Contents

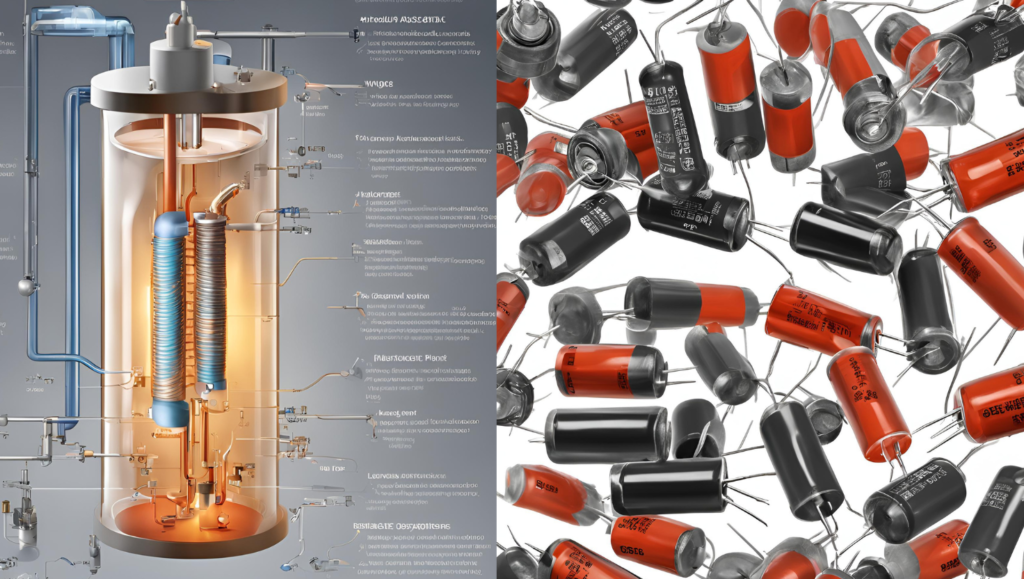

Electrolytic capacitors serve as essential components within electronic components networks for powering different devices across power supplies, audio system circuits and signal processing modules. One of the key components of these capacitors is the electrolytic capacitor electrolyte, which plays a critical role in their operation. This article will explore the function, types, and importance of the electrolytic capacitor electrolyte in detail, as well as its daily-life applications

A capacitor named the Electrolytic Capacitor exists among electronic components.

Due to the presence of an electrolyte the electrolytic capacitor achieves enhanced capacitance in comparison with all other types of capacitors is able to provide. These capacitors are polarized, meaning they have a positive and negative terminal, and the electrolytic capacitor electrolyte forms part of the dielectric between the anode and cathode of the capacitor.

Electrolytic capacitors operate in power supply circuits to deliver high capacitance requirements and stabilize electrical voltage and energy storage while redirecting power sources. Audio amplifiers and filter circuits together with various electronic devices utilize electrolytic capacitors mainly as decoupling capacitors.

What is Electrolytic Capacitor Electrolyte?

The electrolytic capacitor electrolyte is a conductive solution or paste that fills the space between the anode and cathode of an electrolytic capacitor. The storage of energy in a capacitor depends on electrolyte functionality because it establishes a conductive pathway for electrode charge accumulation. This electrolytic capacitor electrolyte is typically a mixture of water, organic solvents, and a variety of salts, such as ammonium or lithium salts.

There are different types of electrolytic capacitor electrolytes, and each type is designed for specific applications, such as aluminum electrolytic capacitors or tantalum electrolytic capacitors. The performance and lifespan of an electrolytic capacitor are heavily influenced by the properties of the electrolytic capacitor electrolyte.

The Role of Electrolytic Capacitor Electrolyte

The electrolytic capacitor electrolyte plays several crucial roles in the functionality of an electrolytic capacitor:

1. A proper electrolytic capacitor electrolyte needs to possess conductivity to transport electrical current from anode to cathode. High conductivity permits better efficiency for energy storage and release in electrolytic capacitors.

2. Stabilizing the Dielectric: The electrolytic capacitor electrolyte helps stabilize the dielectric layer, which is usually made of aluminum oxide in aluminum electrolytic capacitors. The anode and cathode remain isolated from each other through this insulating oxide layer even though it allows the charging process to occur.

3. The electrolytic device within electrolytic capacitors maintains the required polarity because it establishes proper orientation between positive and negative terminals. The capacitor fails when an incorrect polarity is applied and it leads to destructive outcomes.

4. Various fluctuating temperature environments suit the operational needs of capacitors. The electrolytic capacitor electrolyte helps dissipate heat generated during the charging and discharging cycles, ensuring that the capacitor operates within safe temperature ranges.

- “Electrolytic capacitors and PSC capacitors both regulate power in motors. While electrolytic capacitors store energy, PSC capacitors enhance motor efficiency by providing phase shift.”

Types of Electrolytic Capacitor Electrolyte

The electrolytic capacitor electrolyte comes in different types, depending on the construction and material of the capacitor:

1. Aluminum Electrolytic Capacitor Electrolyte: This is the most common type of electrolytic capacitor electrolyte. The electrolyte consists of water along with organic solvents and salt mixtures which appear as either a liquid or semi-liquid substance. Electrolytic aluminum capacitors find application in diverse uses because they maintain affordability and provide high capacitance values among other available components.

2. Tantalum Electrolytic Capacitor Electrolyte: Tantalum electrolytic capacitors use a solid electrolyte, typically made of manganese dioxide or similar materials. The smaller capacitor size together with better stability and improved reliability makes tantalum electrolytic capacitors more expensive than aluminum electrolytic capacitors.

3. Some advanced capacitors utilize solid polymer electrolytes for their operation. The integration of solid electrolytes provides better stability and conductivity than traditional liquid electrolytes so they appear in high-performance applications.

Factors Affecting the Performance of Electrolytic Capacitor Electrolyte

Several factors can affect the performance and lifespan of the electrolytic capacitor electrolyte:

1. The performance of electrolyte depends directly on environmental temperature measurements. High operating temperatures induce electrolyte degradation through evaporation that weakens capacitance so a capacitor can fail.

2. Voltage: Electrolytic capacitors are rated for specific voltages, and exceeding these limits can damage the electrolytic capacitor electrolyte. Strong electrical overvoltage prompts electrolyte breakdown that results in capacitor internal leakage and may cause capacitor failure.

3. Aging: Over time, the electrolytic capacitor electrolyte can degrade due to chemical reactions within the capacitor. The capacitive performance and equivalent series resistance (ESR) of the capacitor decrease after electrolyte degradation occurs.

4. The aging process of electrolytic capacitors makes leakage one of their frequent failures. If the electrolytic capacitor electrolyte leaks out, the capacitor will lose its ability to store charge, rendering it useless.

5. Current: The amount of current passing through the capacitor can also affect the stability of the electrolytic capacitor electrolyte. Strong electrical current generates high temperatures within the electrolyte that speeds up its decomposition process.

How Electrolytic Capacitor Electrolyte Affects Capacitor Lifespan

The lifespan of an electrolytic capacitor is directly influenced by the quality and composition of its electrolytic capacitor electrolyte. The electrolytic capacitor lifespan together with performance quality improves with higher-quality electrolytes. When electrolytes do not meet standards they shorten the lifespan while decreasing the reliability factor.

Daily Life Applications of Electrolytic Capacitor Electrolyte

Electrolytic capacitors, powered by their electrolytic capacitor electrolyte, are found in a wide variety of everyday products. Transistors powered through electrolytes have several applications because of their excellent efficiency and high capacitance levels.

1. Computer power supplies as well as television supplies and home appliance power supplies incorporate electrolytic capacitors. The electrolytic capacitor electrolyte helps to stabilize voltage and prevent power fluctuations, ensuring the smooth operation of these devices.

2. The electrolytic capacitors used in audio systems serve to smooth electrical signals while stopping signal distortions from occurring. The electrolytic capacitor electrolyte helps maintain high-quality sound in amplifiers and other audio equipment.

3. Home appliances together with televisions use electrolytic capacitors to deliver power smoothly from refrigerators to microwaves. The electrolytic capacitor electrolyte plays a vital role in ensuring that these devices function properly and efficiently.

4. The electronic products that include smartphones together with laptops and gaming consoles need electrolytic capacitors. Electrolytic capacitors control electricity flow and maintain signal quality through signal filtering while also keeping stored energy available. The electrolytic capacitor electrolyte ensures that these devices maintain optimal performance.

5. The electrolytic capacitor and its electrolyte enable the operation of renewable energy devices including solar inverters as well as LED lights. The electrolytic capacitor electrolyte helps smooth the power supply, enabling the energy-efficient operation of these systems.

Frequently Asked Questions (FAQs) About Electrolytic Capacitor Electrolyte

1. The drying out of electrolytic capacitor electrolyte leads to safety problems.

Electrolytic capacitors lose both capacitance ability and generate more equivalent series resistance (ESR) when their electrolyte dries up because the capacitor loses its capability to hold charges correctly. The capacitor becomes unfunctional due to this condition.

2. Is it possible to utilize electrolytic capacitors in high-frequency implementation?

The high ESR levels prevent electrolytic capacitors from performing well under high-frequency conditions. Organizations pick ceramic capacitors or film capacitors as the main choice for high-frequency applications.

3. The average life expectancy of an electrolytic capacitor remains uncertain.

The operational life expectancy of electrolytic capacitors depends on multiple parameters including temperature level and applied voltage strength together with usage environment elements. The operational life of electrolytic capacitors ranges from 1,000 to 10,000 hours based on their quality level.

At last

The electrolytic capacitor electrolyte is a fundamental component in the design and operation of electrolytic capacitors. It plays a vital role in the performance, stability, and longevity of these capacitors. Understanding its importance can help engineers and hobbyists make better choices when selecting capacitors for their projects, ensuring reliable operation and extended lifespans.

In summary, the electrolytic capacitor electrolyte is what allows electrolytic capacitors to store energy and perform their essential tasks in electronic circuits. Whether in power supplies,