In the world of electrical engineering and motor systems, the Permanent Split Capacitor (PSC) is an essential component that plays a critical role in the efficiency and performance of motors. Multiple applications across HVAC systems and the pump industry value the PSC motor for operational reliability while delivering energy efficiency and simplified maintenance control. This article will delve into the details of Permanent Split Capacitor (PSC) motors, explaining their function, advantages, and common applications.

What is a Permanent Split Capacitor (PSC)?

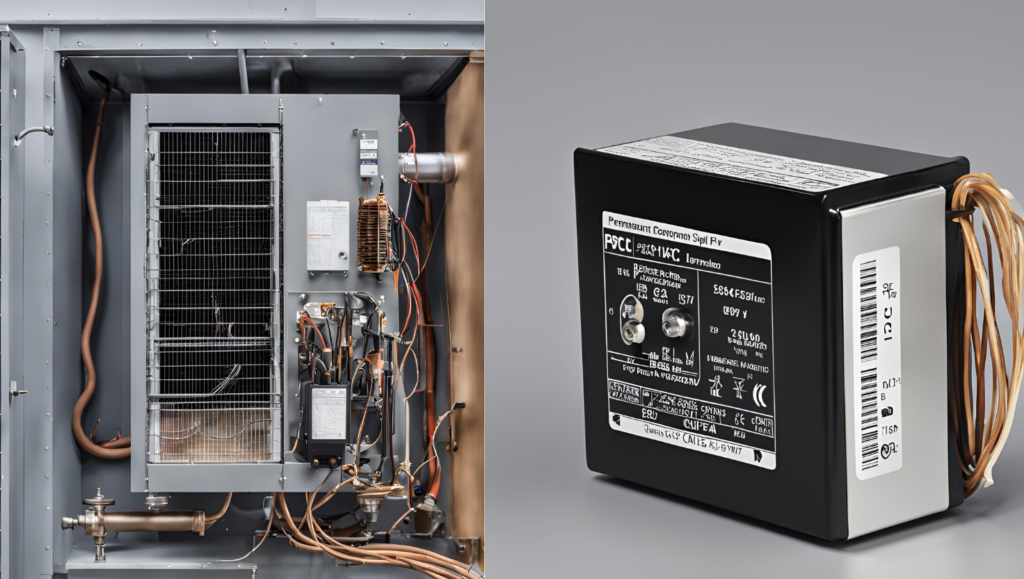

A Permanent Split Capacitor (PSC) is a type of electric motor that uses a capacitor in the circuit to improve its efficiency. During full operation time the PSC motor holds its capacitor within the motor circuit while other motor types do not. The capacitor works as a fixed component in the motor because you cannot disconnect it during operation.

In a PSC motor the capacitor helps enhance both power factor performance and overall efficiency through phase adjustment. The phase shift permits the development of a rotating magnetic field which boosts the production of motor torque. The Permanent Split Capacitor (PSC) motor is designed to run continuously with the capacitor connected to the motor’s winding.

How Does a Permanent Split Capacitor Motor Work?

The Permanent Split Capacitor (PSC) motor works by using a capacitor in the motor’s starting winding to create a phase shift between the current in the start and run windings. The phase shift produced something essential for operating motors since it generates a rotating magnetic field.

A PSC motor features a capacitor connected to the motor windings which does not break connection during motor operation. The motor’s operational efficiency improves because the capacitor supplies smooth performance while minimizing power losses. This motor functions using alternating current and its integrated capacitor streamlines power use to create a more effective energy solution.

Advantages of Permanent Split Capacitor Motors

There are several key advantages to using Permanent Split Capacitor (PSC) motors in various applications:

- Energy Efficiency: Through its design the PSC motor achieves high operational efficiency by consuming less power and the savings in tasks improve overall operating expenses. The enduring presence of the capacitor enables perfect phase management which leads to reduced power waste together with enhanced motor performance.

- Reliability: The Permanent Split Capacitor (PSC) motor is known for its durability and long lifespan. The permanent capacitor design eliminates frequent replacement and servicing requirements which renders the motor dependable for uninterrupted operation.

- Smooth Operation: Operating smoothly thanks to an integrated capacitor the PSC motor minimizes start-up problems like stalling and vibration. The resulting operation produces lower noise levels but also reduces mechanical stress on motor components over time.

- Low Maintenance: The simple construction of the PSC motor eliminates both start capacitor and centrifugal switch components reducing the overall maintenance requirement for other motor variants. Applications that must remain reliable while demanding little maintenance receive the best performance from this motor type.

- Cost-Effective: The PSC motor represents an affordable option for production and maintenance which results in substantial cost savings across industrial and commercial uses.

Applications of Permanent Split Capacitor Motors

The Permanent Split Capacitor (PSC) motor is used in a wide variety of applications due to its energy efficiency, reliability, and low maintenance requirements. Some of the most common applications include:

- HVAC Systems: Heating ventilation air conditioning systems make up the chief functioning area for Permanent Split Capacitor motors. This motor operates fans and blowers which create the essential airflow needed for temperature control systems.

- Pumps: The Permanent Split Capacitor (PSC) motor serves as a common choice for pump applications in systems including water circulation installations as well as irrigation setups and pool pumps. Because of the motor’s smooth performance, pumps maintain reliable operation while remaining efficient.

- Fans: Permanent Split Capacitor (PSC) motors are used in various types of fans, including ceiling fans, exhaust fans, and ventilation fans. The design of these motors produces constant airflow while requiring minimal energy input.

- Appliances: PSC motors power the drive mechanisms of washing machines, refrigerators, and air conditioners by running their internal fans, pumps, and compressors. These motors achieve perfect suitability for these applications because of their excellent energy efficiency and minimal maintenance requirements.

- Industrial Equipment: A number of industrial machines operate with PSC motors that power devices such as conveyors alongside mixers and compressors. These motors stay operational all day while running efficiently which leads to widespread adoption in multiple industrial fields.

Difference Between Permanent Split Capacitor and Other Motors

The Permanent Split Capacitor (PSC) motor is often compared to other types of motors, such as the Capacitor Start Motor and the Induction Motor. These motors differ primarily based on capacitor function and application throughout motor operation.

- Capacitor Start Motor: During operation, this motor type utilizes a capacitor solely for starting while running above start speed it no longer requires the capacitor. As the motor achieves its operating speed the system incurs at automated points disconnects the capacitor. By differing from other designs the Power Split Capacitor motor maintains the capacitor connected during its whole operation cycle.

- Induction Motor: The PSC motor takes induction motor design further through the integrated capacitor which boosts its efficiency. Standard induction motors operate without capacitors therefore their efficiency lags behind that of PSC motors.

Daily Life Uses of Permanent Split Capacitor Motors

The Permanent Split Capacitor (PSC) motor is present in many devices and systems that we use every day. Here are some common daily life uses and where you can find these motors:

- HVAC Systems: HVAC systems that control environmental conditions in residential buildings maintain their stability through PSC motors. HVAC devices utilize the motor to run blowers and fans which move air across heating and cooling components. Such power efficiency keeps systems performing optimally while establishing the targeted temperature and maximizing energy savings.

- Ceiling Fans: PSC motors power ceiling fans because they operate with high efficiency without generating excess noise during long periods. Engineered precisely for performance efficiency this motor provides delicate fan blade rotation and conserves power.

- Refrigerators and Freezers: Compressor systems in household refrigerators and storage-freezers use PSC motors. The motor operates as the critical component that moves refrigerant through the system since this distribution maintains cooling operations. Continuous operation capability enables these motors to demonstrate exceptional reliability throughout extended durations of use.

- Washing Machines: The drum and agitator in numerous washing machines receive their power from PSC motors. During washing and spinning cycles the motor provides consistent operation. The PSC motor proves to be an ideal selection for washing machines because of its low maintenance needs together with high energy efficiency during prolonged operational periods.

- Air Purifiers: Air purifiers operate their fans for air filtration through PSC motor operation. The motors function with silent operation along with high efficiency to ensure homes and offices receive purified air.

Why is the Permanent Split Capacitor Motor So Popular?

The Permanent Split Capacitor (PSC) motor is widely used due to its many advantages, including:

- Energy Efficiency: The PSC motor operates with less power than most other motor types which makes it an economical choice for devices that maintain continuous power usage. Through its efficient design residential homes and businesses experience reduced cost on electricity bills.

- Reliability: The Permanent Split Capacitor (PSC) motor features designs allowing prolonged operation without maintenance requirements. Applications which demand dependable functioning from their motors should use PSC motors as they work perfectly in HVAC systems and industrial equipment.

- Smooth Operation: Because of its permanent capacitor design the motor operates without unnecessary vibrations while reducing sound output. PSC motors function quietly in appliances which makes them perfect for devices like refrigerators and ceiling fans.

- Low Maintenance: The persistent nature of the built-in capacitor allows both maintenance needs and replacement procedures to become unnecessary. Continuous motor applications gain substantial benefits from this function because maintenance expenses decrease as a result.

- Cost-Effective: Because PSC motors require little expenditure during manufacture and upkeep PSC motors attract both manufacturers and consumers.